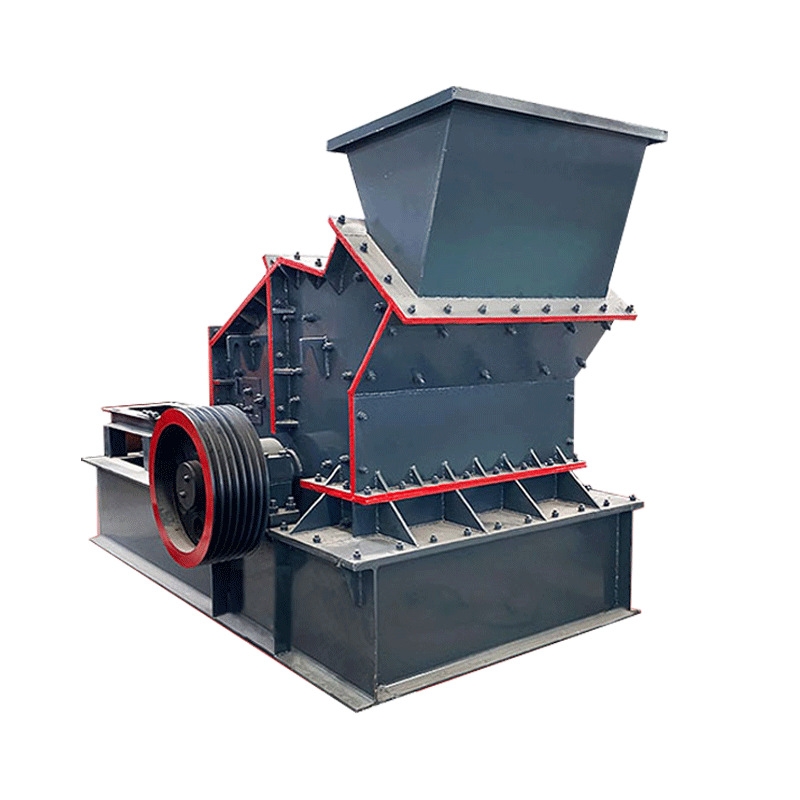

Hydraulic Open-box Sand Making Machine

The Hydraulic Open-box Sand Making Machine combines the advantages of third-generation sand makers, hammer crushers, impact crushers, and vertical shaft impact crushers. It features a large arc-shaped crushing chamber that employs the "stone hitting stone" principle, with a screening chamber for efficient material classification. This innovative design allows specialized fine crushing hammers to function similarly to jaw crushers, significantly reducing operational costs. Developed from years of expertise in mining machinery, this high-efficiency, low-energy device is recognized for its reliability and performance in various industries, including ores, cement, and metallurgical slags.

- 230-520 mm

- 20-270 t/h

- sale1@hnmineeq.com

- 0086 16638156296

- Information

Hydraulic Open-box Sand Making Machine

⊙Product introduction

The Hydraulic Open-box Sand Making Machine integrates the advantages of the third-generation sand maker, hammer crusher, impact crusher, and vertical shaft impact crusher. This sand maker features an oversized arc-shaped crushing chamber that utilizes the "stone hitting stone" self-impact crushing principle. The crushing chamber includes a screening chamber with grid slots. Our company has developed specialized fine crushing hammers that achieve a revolutionary breakthrough by allowing the hammer crusher to function like a jaw crusher, thereby significantly reducing operational costs for fine crushing.

The Hydraulic Open-box Sand Making Machine is the culmination of our experts' years of research and development in mining machinery. It is an internationally advanced, high-energy, low-consumption device that plays a vital role among various fine crushing equipment for ores. This machine is currently one of the most effective and reliable stone crushing machines available.

Since the production of our sand maker, we have achieved an outstanding market share in the national market, with product performance continuously improving, earning the trust of our customers. This product is widely applied in various industries, including ores, cement, refractory materials, aluminum silicate clinker, emery, glass raw materials, manufactured building sand, stone materials, and various metallurgical slags.

⊙Features

Versatile Crushing Mechanism: Combines the principles of third-generation sand makers, hammer crushers, and impact crushers for effective material processing.

Large Arc-Shaped Crushing Chamber: Designed to maximize the impact of materials, utilizing the "stone hitting stone" principle for efficient fragmentation.

Specialized Fine Crushing Hammers: Features innovative hammers that can function like jaw crushers, providing a revolutionary approach to fine crushing.

Quick Maintenance: The open-box design allows for easy access to replace hammers and other components, minimizing downtime and facilitating rapid maintenance.

High Efficiency and Low Energy Consumption: Engineered to operate with minimal energy costs while maximizing output, making it an environmentally friendly choice for various industries.

⊙Product Parameters

| Model | Feed port sizer (mm) | feed port (mm) | Discharge particle (mm) | Discharge adjustment width (mm) | Cement clinker output (t/h) | Limestone yield (t/h) | Glass sand yield (t/h) | power (kw) |

| 800*400 | 400*230 | 120 | ≤ 5 | 5-20 | 20-30 | 30-45 | 35-45 | 22-37 |

| 800*600 | 600*230 | 180 | ≤ 5 | 5-20 | 35-40 | 40-55 | 45-55 | 37-45 |

| 800*800 | 800*230 | 180 | ≤ 5 | 5-20 | 35-45 | 60-65 | 55-65 | 45-55 |

| 1010*1010 | 1000*330 | 180 | ≤ 5 | 5-20 | 45-55 | 60-75 | 65-75 | 55-75 |

| 1200*1000 | 1200*330 | 180 | ≤ 5 | 5-20 | 80-110 | 80-100 | 80-100 | 90-110 |

| 1200*1200 | 1200*420 | 180 | ≤ 5 | 5-20 | 100-110 | 90-100 | 90-120 | 110-132 |

| 1400*1400 | 1400*420 | 190 | ≤ 5 | 5-20 | 100-150 | 100-150 | 120-150 | 160 |

| 1600*1600 | 1600*520 | 190 | ≤ 5 | 5-20 | 170-210 | 190-250 | 190-250 | 250 |

| 1800*1800 | 1800*520 | 190 | ≤ 5 | 5-20 | 250-270 | 280-310 | 280-310 | 315 |

⊙Application Field

Hydraulic Open-box Sand Making Machine operates with stable and reliable performance, featuring a simplified process, straightforward structure, and easy maintenance. It boasts a high production capacity and a long lifespan for the hammers. This machine is widely applicable for fine crushing of various minerals, including granite, basalt, limestone, pebble, cement clinker, quartz, iron ore, and bauxite. It is also used in producing aggregates for artificial sand, high-grade highways, railways, hydropower, airports, construction, cement, refractory materials, and metallurgical industries.

⊙Machine Structure and Working Principle

Hydraulic Open-box Sand Making Machine consists of several key components, including the rotating part, casing, and impact plates. The rotor is equipped with multiple non-overlapping hammer racks that hold hammers fixed in place. When the machine operates, materials enter the crushing chamber where they are impacted by high-speed hammers. This action crushes the materials using a “stone-on-stone” principle, resulting in fine particles. The design features a large curved crushing cavity and a screening area with grate slots, allowing for efficient material classification. The hydraulic opening mechanism facilitates quick access for maintenance, enabling easy replacement of hammers and other wear parts, thus ensuring continuous operation and minimizing downtime.

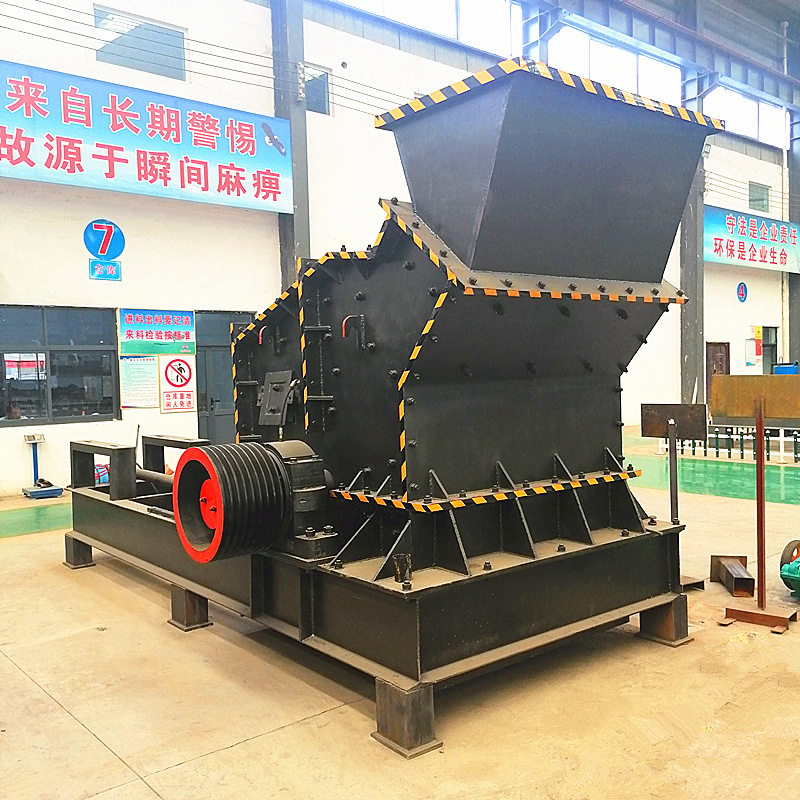

⊙Factory product display

The factory product display for the Hydraulic Open-box Sand Making Machine showcases its advanced design and robust construction. The machine is presented in a clean and organized environment, highlighting its key features such as the hydraulic opening mechanism for easy maintenance, the large curved crushing cavity for efficient operation, and the high-quality materials used in its manufacture. Each unit is displayed with accompanying information on its specifications, performance capabilities, and applications across various industries, including mining, construction, and cement production. This setup not only emphasizes the machine's versatility and reliability but also reinforces the company's commitment to quality and innovation in mineral processing equipment.